MANUFACTURING EXECUTION SYSTEM

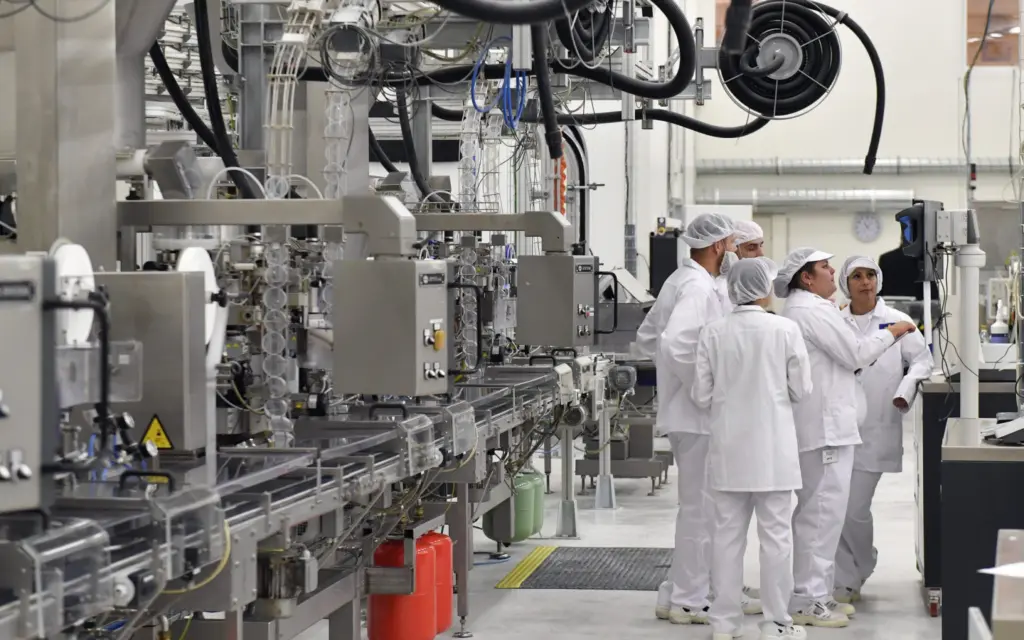

Manufacturing Execution System and Laboratory Information Management System development

ERPMANUFACTURINGSAP

MES and LIMS system were created for the tobacco factory, which is part of the international company included in the Global TOP 3.

The system is implemented and used at all stages of the production cycle, from the materials and ingredients feeding to the finished goods accounting and moving. An integration with the existing ERP WMS and SCADA systems, that allows to:

In 2009, the general strategy of the company was to implement the highest standards of process performance and quality assurance in all factories around the world. As a result, the management relied on increasing the level of automation in the processing and distribution of information in production, thereby increasing economic efficiency through instant KPI assessment and the rapid identification and elimination of negative factors.

Our task was to design and implement a unique system that unites the following main features:

Engineering team spent 2 month in the production facilities to learn about the production processes and coordinate with engineering team.

Linux (Centos, Red Hat, OpenSuSe), Windows 7,10

MongoDB, Oracle 19c, PostgreSQL 12

Java 11, Kotlin, Swift, JavaScript, Python 3, BASH, Powershell

Spring, Java enterprise server, React, Realm, OpenCV, Tensorflow

Java enterprise server, Tomcat, AWS EC2, AWS S3, AWS Lambda, Amazon SageMaker

Jenkins, Docker, Nginx

AWS EC2, AWS S3, AWS Lambda, Amazon SageMaker

Amazon SageMaker, Tensorflow, PyTorch

SAP ERP 6.0. SCM/CRM/HRM

ISO 25010, ISO/IEC 12119, ISO/IEC 27000

Complex production processes analytics (deep knowledge of manufacturing value stream chain).

Designing large-scale systems to solve complex, multi-level, and diverse business problems.

Effective interaction with corporate vendors (including engineering companies) and stakeholders located in other countries.

Customized effective production management systems (MES level) that help not only promptly to control and manage processes, depending on the situation to make rational decisions, but also apply Lean Manufacturing methods such as continuous improvement tools based on constant tracking of trends of changes processes parameters, forming flexible analytical reports and constant progress monitoring.

All rights reserved. Any unauthorized copying is strictly forbidden.

Privacy policy | Cookies

Soft Industry Alliance website employs cookies to improve your user experience. We have updated our cookie policy to reflect changes in the law on cookies and tracking technologies used on websites. If you continue on this website, you will be providing your consent to our use of cookies.

For detailed information how we handle data and about the Cookies we use, see our Privacy Policy and Cookies page.